Cuando las organizaciones de fabricación integraron las máquinas de medición de coordenadas en sus procesos en la década de 1960, su principal objetivo era inspeccionar los productos fabricados para garantizar que las dimensiones clave estuvieran dentro de sus especificaciones. Treinta años después, surgieron las tecnologías de escaneo de nubes de puntos e hicieron posible digitalizar rápidamente y analizar el herramental, las piezas de los prototipos y los ensamblajes piloto para reducir el tiempo para comercializar mientras se diseña un nuevo producto. Ahora que ya integramos satisfactoriamente los flujos de trabajo de análisis dimensionales y control de calidad en una solución única, es posible implementar una plataforma de medición 3D común para todo el ciclo de vida de ingeniería de producto y fabricación.

Libro blanco

Recopilar mediciones 3D fiables

El enfoque en la metrología 3D inteligente

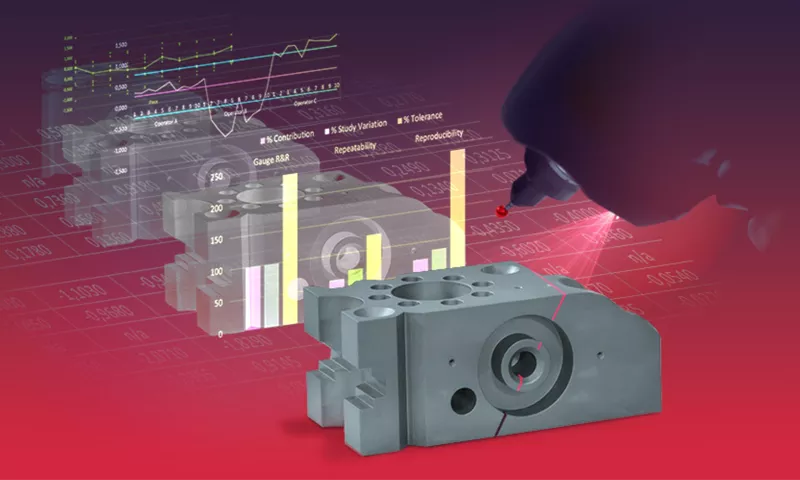

Los metrólogos saben que los sistemas de medición no son perfectos. Al realizar un análisis del sistema de medición (MSA), se pueden identificar los componentes de variación en el proceso de medición y tomar las medidas correctivas para garantizar que represente, como máximo, el 30% de las desviaciones medidas.

Artículo

Realidad mixta: El avance más destacado en metrología 3D a gran escala desde el laser tracker

La emergente tecnología de la realidad mixta está transformando la metrología a gran escala optimizando los beneficios de los laser trackers y ofreciendo las mismas ventajas que los proyectores y los controles remotos y, al mismo tiempo, excede sus limitaciones. Entre las nuevas y formidables capacidades de las gafas inteligentes junto con el potente software de medición 3D se encuentran los gráficos de guía y las instrucciones de medición superpuestas a la pieza medida, lo que garantiza que los operadores midan siempre las entidades geométricas correctas y obtengan información de medición en tiempo real.

Artículo

Unifique sus operaciones de metrología 3D con una plataforma de software universal

En la actualidad, las empresas de fabricación disponen de sofisticados laboratorios de medición 3D con dispositivos portátiles y CNC CMM, escáneres láser, laser trackers y galgas digitales, y cada marca de hardware utiliza sus propias soluciones de software. Al depender de varios programas de software, se deben dominar varios flujos de trabajo, lo cual dificulta el rendimiento de los equipos de medición 3D. La sustitución de estos programas por una plataforma universal de software resuelve las dificultades de los equipos de medición y aumenta considerablemente la eficiencia operativa de la metrología 3D.